Ace Fix-it Hardware Dubois Dubois, Pa

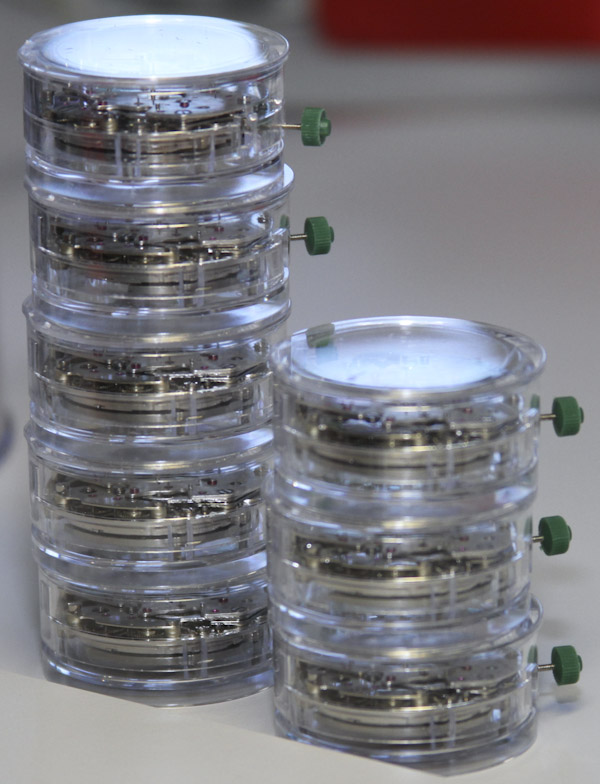

Fresh movements come in these plastic containers

On an uncommonly warm twenty-four hours in early October I visited a place few watch writers get – the industry (well one of them) of Dubois-Depraz. High-up in the mountainous region of Switzerland's famous Vallee de Joux the factory sits amid many famous watch brands. Dubois-Depraz is a key cog in the watch industry you know and beloved, but they don't make watches.

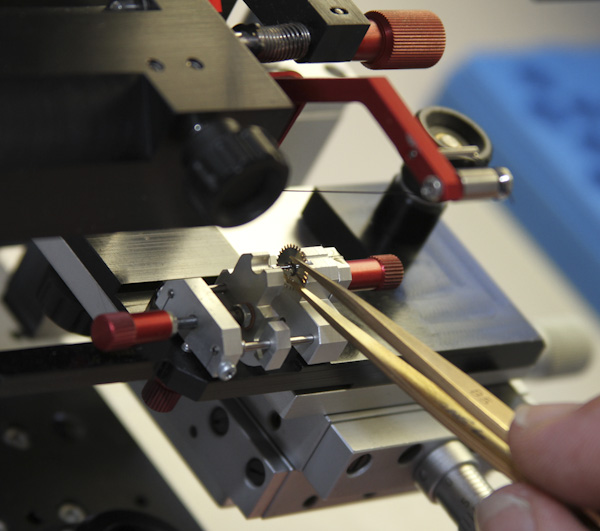

Private gears are meticulously tested for precision and utility

Different the many curated tours of watch factories I am subject to, my guide at Dubois-Depraz wasn't a PR guide. He probably just spoke English language a flake better than the other people there. The manufacture is operated by two of the three Dubois brothers, and it has been in the family since its inception in 1901. The component maker currently is comprised of iii locations, and I got to visit the most important facility – the assembly plant.

The air of the facility is very industrial. There is a scrap more hustle and bustle here than in many other watch manufactures – but the white lab coat attire is familiar. Noisily machines operate as ambient sound fills the room with the repetitive operations of pins being connected to plates and gears being tested. Parts aren't really produced at this location – that is however generally done by Dubois-Depraz, merely elsewhere. Here parts are tested and put together into their final forms. I find that the type of person here is unlike than in-house equally about brands. The workers are older, more mature looking. It is very common for the boilerplate age of people working at even the highest-end sentry manufactures to be about 25. Dubois-Deprez has a more than lived in experience that is comforting.

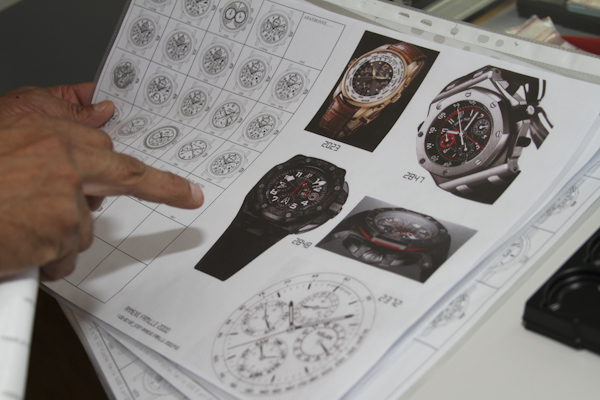

Audemars Piguet & Girard-Perregaux are just some of Dubois-Depraz's ongoing clients

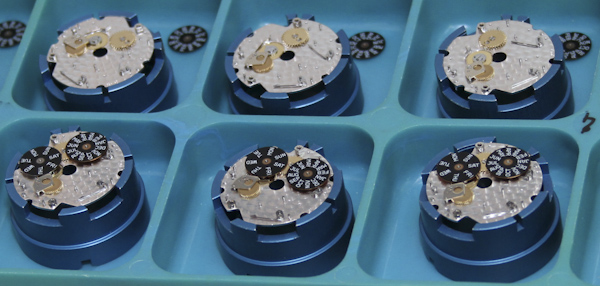

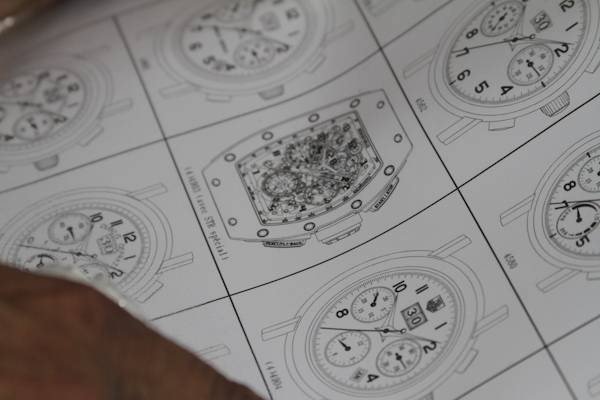

In addition to chronographs, Dubois-Depraz specializes in agenda modules

Without trying to be fancy the workers plow through the tiresome effort of assembling picket move modules. Their construction is very similar to complete watch movements, and they each all the same take months to complete given the bevy of steps involved from commencement to finish. What people really don't quite understand is that even your bones mechanical watch movement takes a lot time to put together. Information technology is a affair of weeks if not months, and the movements pass through the hands of many people who each construct, inspect, decorate, assemble, and test. And sometimes the steps are repeated more than than once. Seeing simply parts of the procedure makes one empathize non merely what makes a Swiss watch "Swiss," merely why they aren't inexpensive. There is real endeavor and fourth dimension in these little items of passion that the Swiss won't finish making until time itself is a concept we take forgotten.

Even many Richard Mille chronograph watches have a lot of Dubois-Depraz in them

Chronograph gears are ultra-fine and involve delicate assembly

As mentioned, Dubois-Depraz is not a watch move maker. A watch movement is the basic mechanism for storing and releasing power in guild to indicate the fourth dimension. It is comprised of a mainspring barrel, an escapement assembly, and some gears that move hands. What Dubois-Depraz makes are modules that tin can sit down on base movements (such as the ETA 2892 which is a very popular choice for a base of operations movement) and adds additional functionality. There certainly are "wholly integrated" movements that include time-telling as well equally other functions, but information technology is very expensive to develop these. It makes a lot more sense in most instances to employ a tried and true base movements with a module placed on summit of it to add a chronograph, calendar, etc…

Dubois-Depraz has a long list of talents and clients, merely their unofficial specialty are chronograhs and calendar mechanism. They likewise like making movements that feature both. Making a reliable chronograph is a pain, and many important brands work with Dubois-Depraz for a host of needs ranging from entire movement modules to specific hard to industry parts. You'd honestly be surprised at who uses their services on a regular basis.

Average worker here is a bit more than mature than those working in-house at many brands

Some of Dubois-Depraz'south largest clients are major brands in the Swatch and Richemont Group – also as Rolex. Yeah, fifty-fifty Rolex relies on Dubois-Depraz for at least a few important parts in some of their movements. Brands I know they piece of work with include Breitling, Omega, Jaeger-LeCoultre, Rolex, Patek-Philippe, Audemars Piguet, Richard Mille, and a lot others. For case the chronograph part of the movements in many Audemars Piguet Imperial Oak Offshores are produced here at Dubois-Depraz. It might be surprising, fifty-fifty thought-provoking to larn that proud and of import brands such of these rely on external suppliers for parts and expertise. That is one way of looking at information technology, especially given how much brands like to talk themselves up in terms of their technical achievements. Another way of looking at information technology is to simply sympathise the nature of "Swiss Fabricated."

Switzerland is a homogenous collectivist lodge. They believe that Swiss is best, merely that the Swiss must as well work together for the mutual expert. That is especially true in the watch making globe where things get pretty incestuous. Equally long as you are mingling with Swiss (and to a big extent Germans and the French), things are a gonna exist OK in their eyes. For me, Dubois-Depraz offers an expert service, and they do it well. If Patek Philippe or Jaeger-LeCoultre comes to them for parts, it is considering they probably do a pretty proficient task.

Efficent practices has Dubois-Depraz producing over 100,000 movement modules each yr

Palette jewels set past paw into tray for automated placement into modules

Years of developing special modules for dozens of brands has given Dubois-Depraz a very large catalog of watch modules they can produce. They generally work with base ETA movements, merely too often with Girard-Perregaux and Jaeger-LeCoultre base movements as well. At that place is some extremely high-end work that goes on here, and near of their client projects are totally confidential until completion.

Spending time at their industry helped me capeesh just how circuitous a chronograph mechanism is to brand. Non necessarily in terms of sheer applied science, but rather at how each cam, pinion, and gear must be painstakingly tested for precision and durability. I saw patient workers identify individual gears into microscope machines used to ensure the gears spun perfectly with out fluctuant. Some other automobile was used to test the precise torque of springs used to reset chronograph hands to their starting position. Fifty-fifty the insertion of a pinion into a gear is done carefully, and by hand – each time. According to Dubois-Depraz they produce on the low end nigh 120,000 watch modules per year.

The product of modules is very similar to that of base of operations movements

Banners for the visitor around town

I gained a lot of respect for the chronograph subsequently visiting with Dubois-Depraz. I also learned a lot more about how the watch industry works. Suffice it to say that educating yourself about the watch industry is like understanding lookout man movement. From the surface if can appear decorated and impressive, but you really need to get inside of it to showtime understanding the nuances and run into how things work together (for the amend or the worse). Thanks to the Dubois brothers and cheers to the people at Dubois-Depraz for their open doors.

0 Response to "Ace Fix-it Hardware Dubois Dubois, Pa"

Post a Comment